Building for a Circular Economy

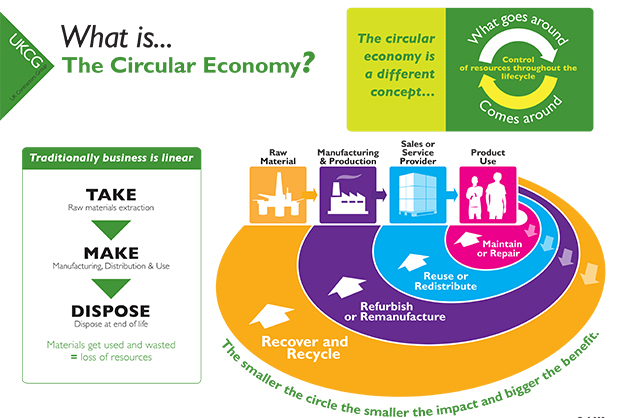

Construction and demolition waste makes up 40% of Australia’s total waste generation and the concept of Circular Economy (CE) might be the answer on how to eliminate this wastage. CE goes beyond green and smart building design. It shifts away from the typical ‘take, make, use, dispose’ approach and focuses on the whole building life cycle by designing, using and recovering building materials for future use.

Building a CE requires collective expert effort from architects, engineers, manufacturers and builders to identify where resource wastage exist within the built cycle. Then, by using circular business models, these resources can either be re-designed to eliminate wastage in the built process or use alternative raw materials were wastage can be reused in the development of other products. Not only can this create greater efficiency in the built process, it could potentially eliminate waste altogether.

Circular Business Models

Circular design

Circular design is one of the business models a company can adopt to contribute to CE. Architects, engineers and manufacturers have an opportunity to work together to design buildings with disassembly in mind so resources can be fully recycled at the end of its life cycle. Products can be designed to use less virgin material or find alternative sustainable resources, such as the aluminium used in Hurricane ventilator that is a 100% recyclable and sustainable metal.

German Architecture firm Architekten Cie employed the circular design model for their project with ABN ARO bank by engineering the building with de-construction in mind, using recyclable materials.

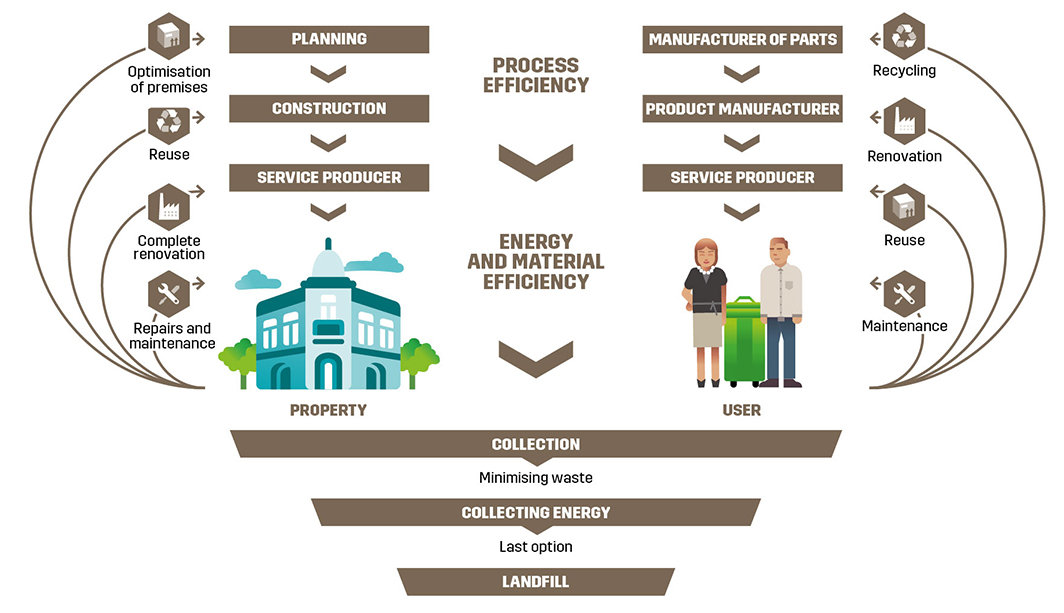

Image from © Lassila & Tikanoja 2013

Circular use

Circular use is about maintaining control over an asset and retaining its value, such as the leasing of products and provision of product maintenance service. This creates an opportunity to engage and create long-term relationships with customers. Niaga, a carpet manufacturer, employed an integrated model of circular design and circular use by producing the carpets using materials that could be deconstructed back into their original form. This ensured 100% of the materials could be recycled into new products.

Circular recovery

Circular recovery presents additional revenue opportunities for manufacturers and suppliers to recover products at their end of life. It is achieved by refurbishing and reselling recovered products. Recovered resource can be re-used in the design and development phase of other products.

The recovery of products doesn’t necessarily have to be a company’s own. CE actively encourages the sharing of resources within industries, especially in the construction sector, to effectively eliminate all waste within an industry as opposed to just waste within a company.

Armstrong Ceilings’ take-back ceiling tile program recovers all tiles, including competitors’, which is then recycled and/or re-used in the development of their own products.

Image from The Chartered Institute of Building

Summary

To succeed in the elimination of construction and demolition wastage, a change in mindset is crucial. We all have to act and understand long term impact of our choices. Innovation is an important element in reducing waste and increasing the efficiency of the built processes. The shift to Circular Economy will not be without its difficulties. However, those who develop circular expertise now would establish themselves as leaders in the industry. You can find more information on a circular building industry here: https://www.ellenmacarthurfoundation.org/assets/downloads/ce100/CE100-CoPro-BE_Business-Models-Interactive.pdf